Since some AR15 style rifles come with a triangular handguard cap, some users might find it necessary to change the handguard cap to a round style. This is necessary if an aftermarket handguard is purchased that requires the use of a round handguard cap. Currently we sell two rifles that come standard with a triangular handguard cap, our base model .308 SRC and our 20″ gov’t rifle. Many handguards, such as the Magpul MOE handguards for example, will fit either round or triangular. But if you purchased a handguard that is specifically made to fit a round handguard cap and you have a triangular one, here’s how to change it out.

First make sure the rifle is unloaded. Then push the takedown pin and pivot pin out and remove the upper from the lower receiver. Remove the bolt carrier and charging handle (see page 14 of your Windham Weaponry Operating and Safety Manual). Then remove the handguards as shown on page 23 of the manual.

Now remove the flash hider with an open end wrench.

If you have a ban compliant gun that has a welded muzzle brake, stop here as those cannot be removed.

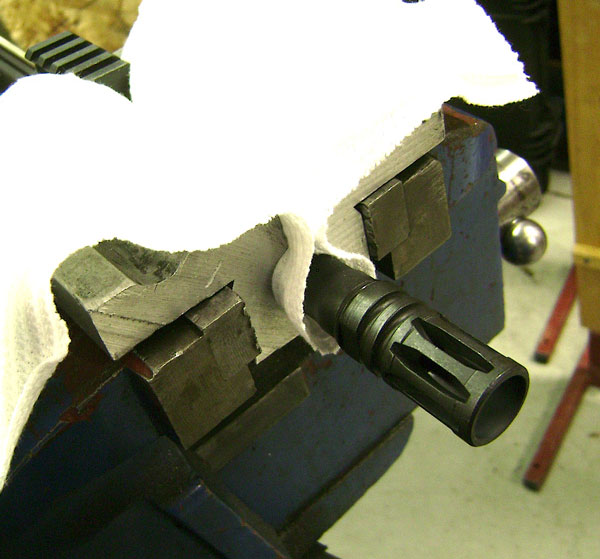

Secure the end of the barrel in a padded set of barrel jaw blocks in a vise and turn the flash hider counter-clockwise (a vise padded with wood will work too, the flash hider only needs about 15-20 foot pounds of torque for removal). Remove flash hider and crush washer and set aside.

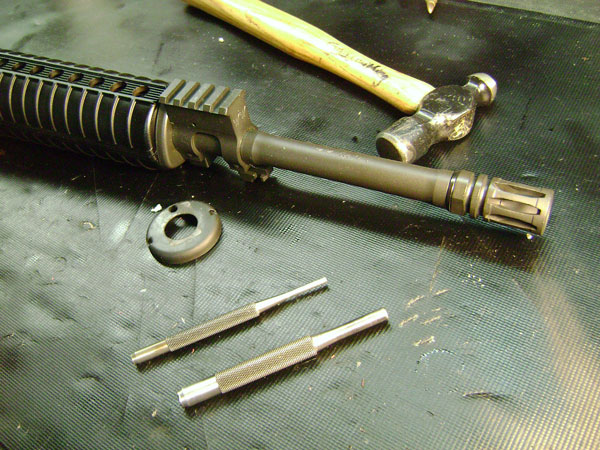

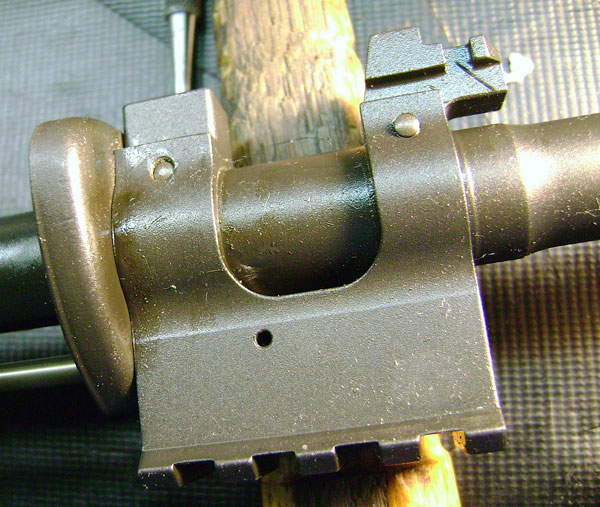

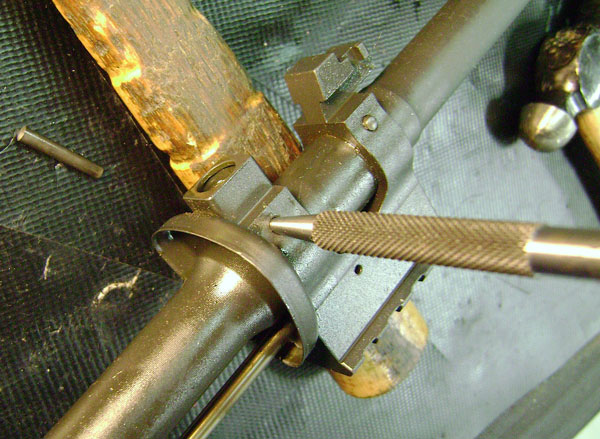

Set gas block on a hammer handle or other similar piece of hard wood so that the taper pins can be driven out of both sides. Taper pins must be driven out from left to right as shown (from the small end of the taper pin). Use a wide flat punch to start the taper pin and push it in flush, then use a 1/8″ punch to drive them all the way out.

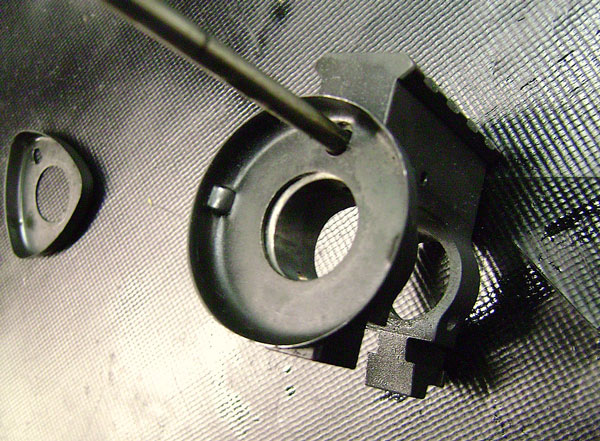

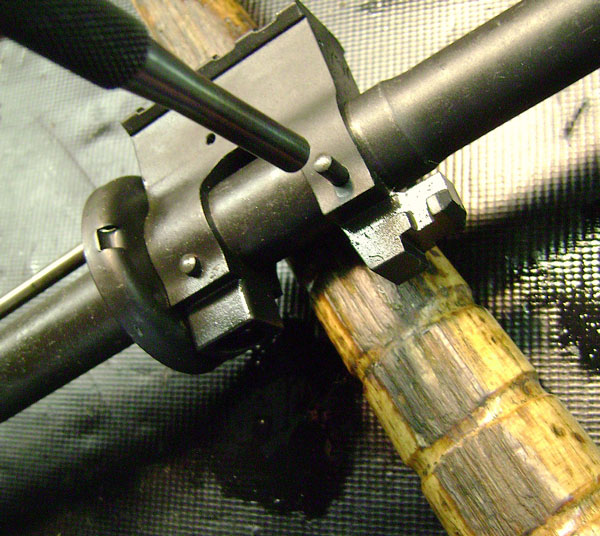

Spray a liberal amount of oil on the outside of the barrel and at the gas block area. With a wooden or plastic mallet drive the gas block/gas tube assembly off the barrel. Remove the triangular handguard cap and replace it with the round one. Wipe any grime off the barrel and gas block then re-oil the barrel. Put the assembly back on the barrel and line up the taper pin holes. Drive the taper pins back in the way they came out through the right side. Make sure the holes are lined up well. If they don’t seem to be going back in, drive them out and realign the holes and start again.

Reinstall crush washer and flash hider, install your new handguard and you are done.

Click here for the round handguard cap in our website catalog.