Sometimes it is necessary to replace the gas key on an AR15 if it becomes damaged or plugged or if a gas key screw is broken. I’ve seen blown primers get wedged down inside which turns the rifle into a single shot. Most times it is impossible to remove it so replacement of the key and screws is necessary. Also damage to the key can happen if the carrier is dropped on the key.

Since the keys are usually pretty heavily staked on, removing the screws isn’t always as simple as just using an Allen wrench and taking them out. Here’s what I do to remove and replace a gas key.

Always wear safety glasses when doing this!

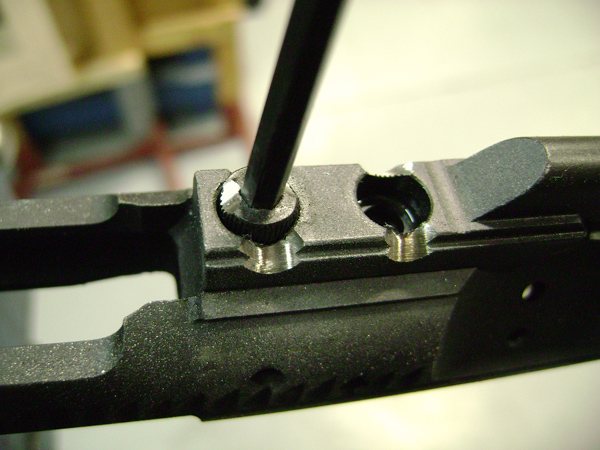

First disassemble the Bolt Carrier. Then put a small grinding stone in a Dremel tool.

Right on top of the stake carefully grind through the staking and slightly into the screw. You need to relieve the area where the steel is pushed into the screw

Do this to all four stakes.

Remove the screws. In this case the front screw came right out with no problems.

The rear screw however still did not want to budge. If it doesn’t want to come, out apply torch heat to the screw and surrounding area. Usually a little heat will help you loosen the screw. It’s important not to damage the screw head. If this happens and the Allen wrench can no longer get a bite on the screw, then you will need to drill the entire screw out. It can be done but you will need a very hard drill bit, so try to avoid that.

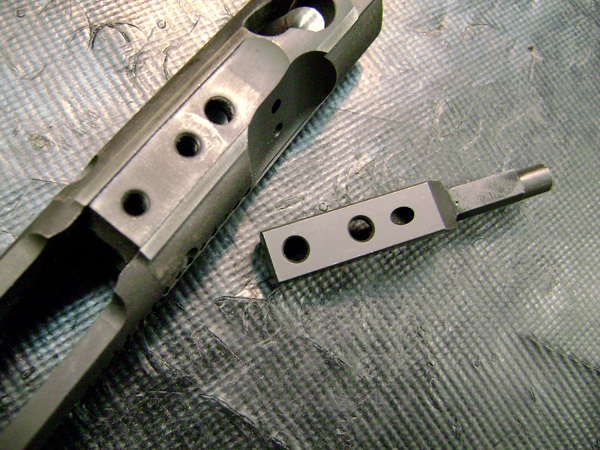

Remove the key and screws, and discard.

Clean the mating surfaces of the carrier and the new replacement gas key. If there is any carbon build up use a solvent and a brush to get all of it off. Also if there is carbon build up in the gas hole (the hole ahead of the screw holes), clean all of that out as well.

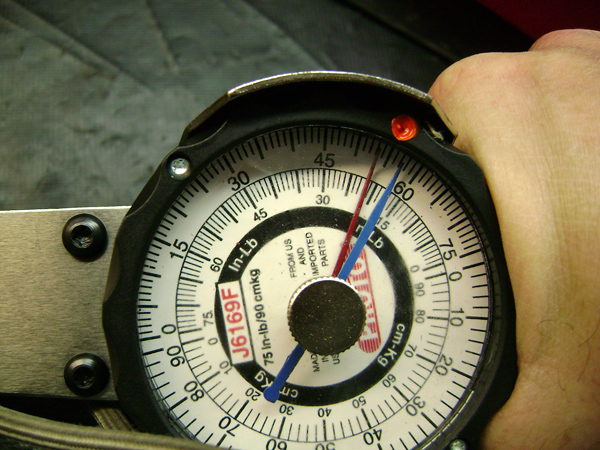

Screw the new gas key into place and snug the screws down. You can do this by hand if you just snug them up good and tight, but if you have access to an inch pounds torque wrench, that is best.

The mil-spec torque is supposed to be between 50-58 inch pounds.

To re-stake the key, I have the luxury of using the gas key press we use on the Production Floor. You most likely will not have access to one of those, so you can stake the key by using a cold chisel to push the edges of the gas key into the screws, or you can use a center punch on top of the gas key next to the screws.

If you ever have questions about your rifle, you are always welcome to call Windham Weaponry Customer Service (Toll Free: 1-855-808-1888). Shoot Safely!